Deburring sheet metal is a vital process in industrial production that brings numerous benefits. By removing burrs and smoothing edges, metal components become safer and more aesthetically pleasing. In the following section, we will discuss the advantages of deburring in the context of product quality and production efficiency.

Blog

We encourage you to read our blog articles.

Edge rounding plays a significant role in the industry, affecting the safety and quality of products. Various processing methods are used in different industries, tailored to the specifics of materials, allowing for optimal results. Attention should be paid to the variety of raw materials requiring edge rounding and the importance of choosing the appropriate technique. This process becomes more efficient and tailored to customer needs, contributing to better quality final products.

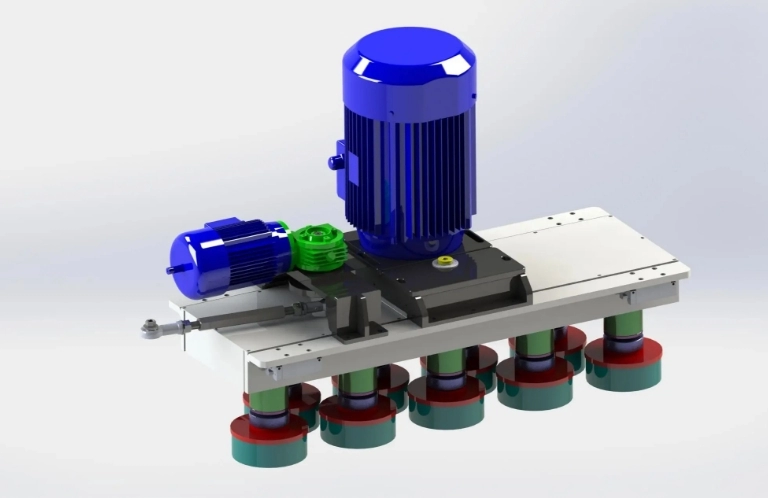

Accurate removal of burrs is crucial for product safety because these small, sharp elements can pose a serious health hazard to users. A burr is not just an aesthetic problem, but primarily a safety concern. This article will discuss the aspects related to this process and its impact on the quality and safety of products, highlighting the importance of paying attention to this element in production.

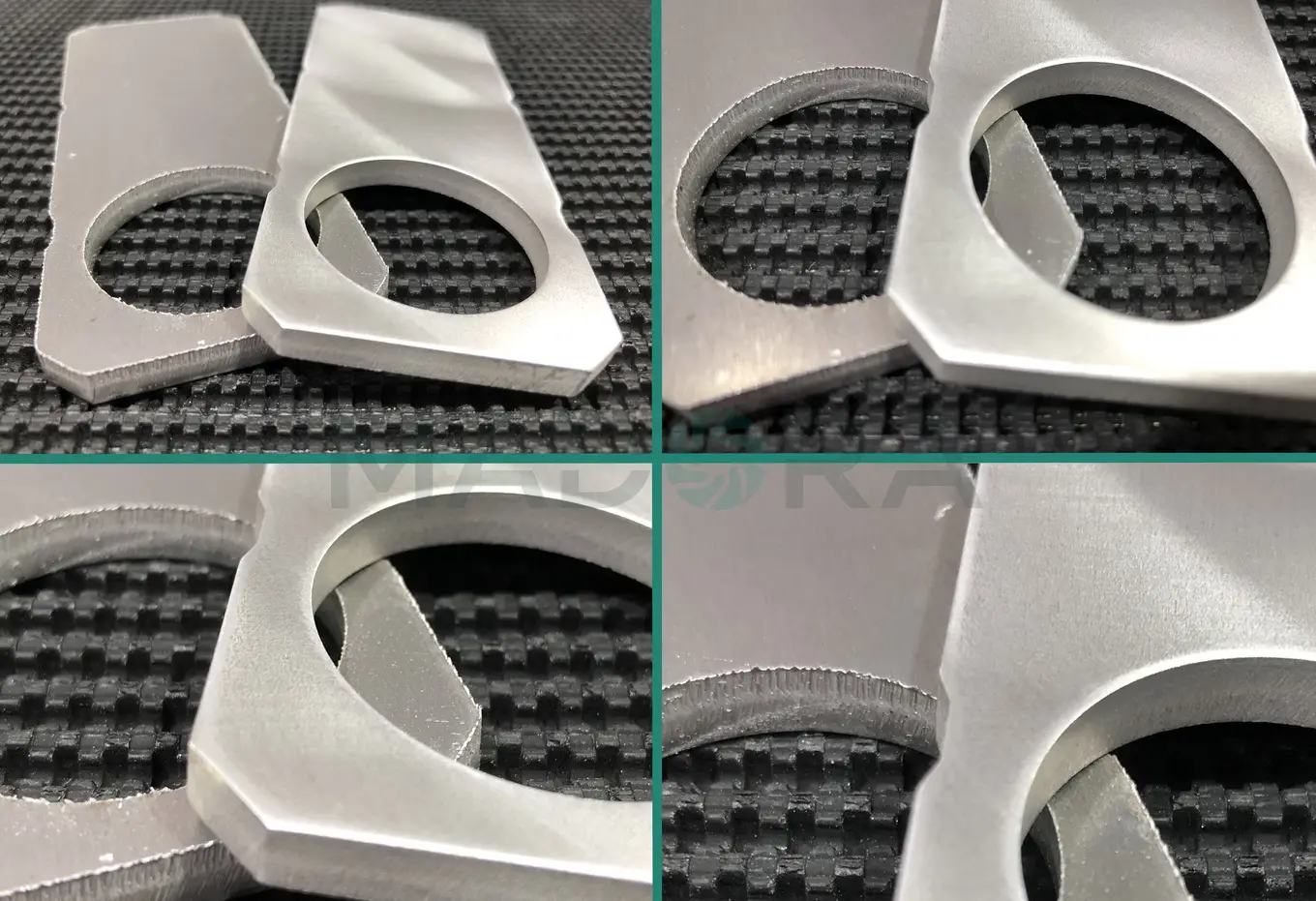

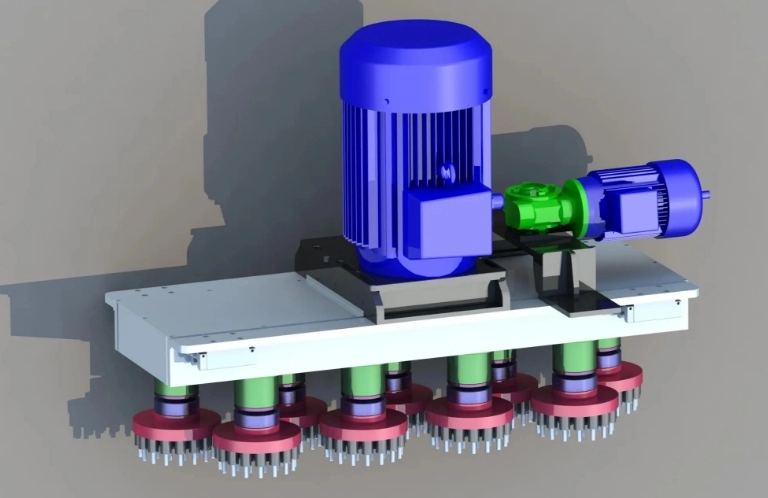

Deslagging discs are essential in oxy-fuel cutting processes, affecting both the efficiency and quality of the operation. They allow for faster and more precise cutting, resulting in time and material savings. It's important to consider the benefits these tools provide and their impact on the overall process efficiency. In the following sections, the advantages of using these discs will be discussed, along with a comparison of different types available on the market.

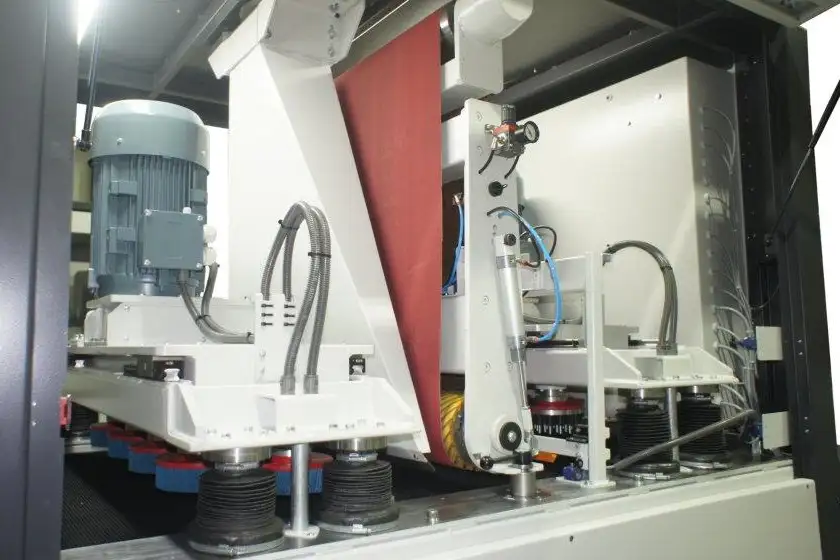

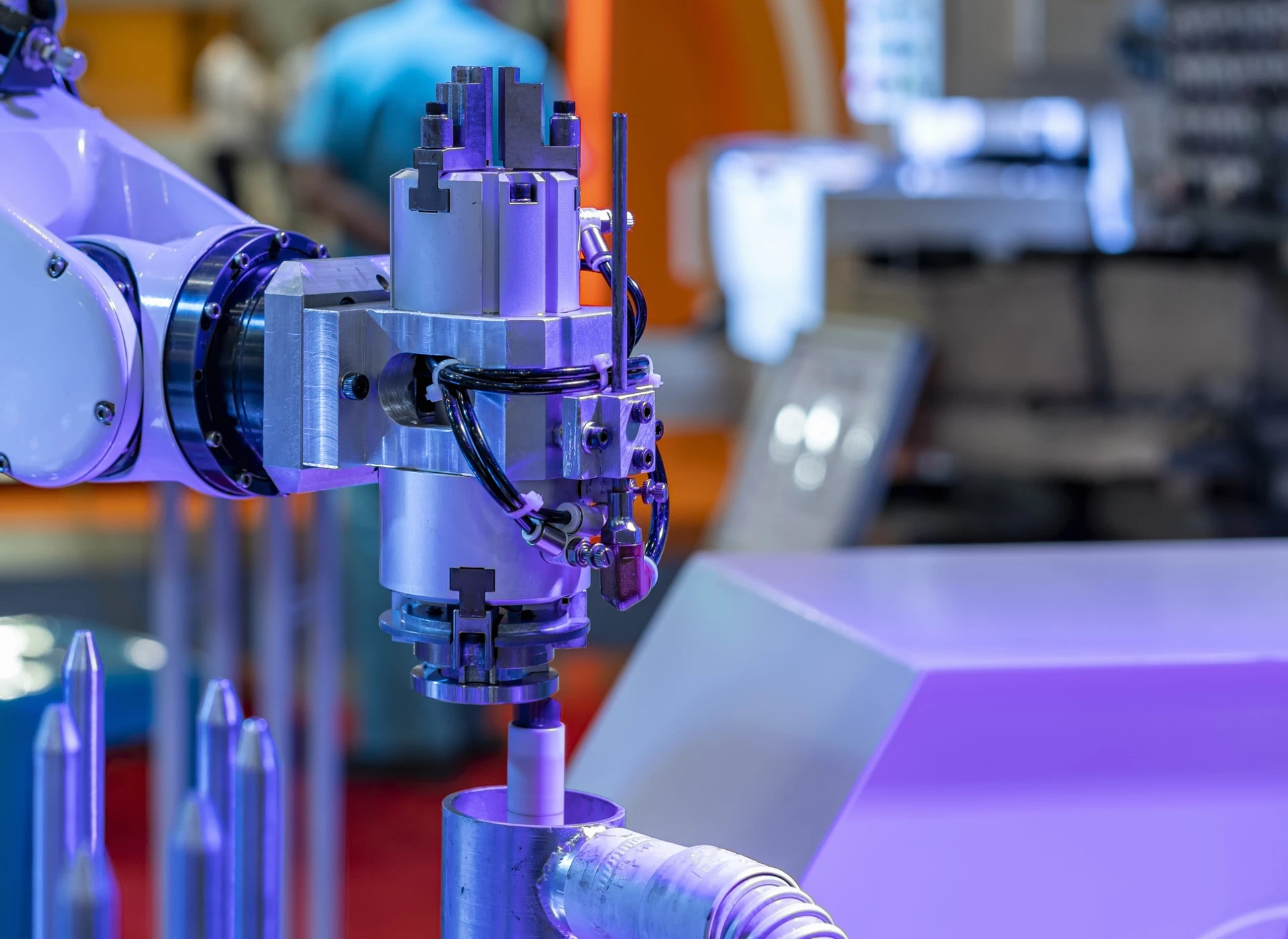

A modern approach to deslagging is crucial in the industry, affecting process efficiency and benefits for manufacturers and users. Innovative technologies in machines designed for deslagging enable precise and rapid actions, resulting in time and energy savings. The application of these solutions across various industries highlights their universality and importance in improving product quality.

The quality of machines plays a key role in the surface grinding process, affecting the precision and efficiency of metalworking. Modern devices enable achieving high-quality surfaces, eliminating imperfections, and ensuring suitable technical parameters.