Edge rounding

The process of edge rounding after water plasma laser cutting or after punching is increasingly required in sheet metal processing. It is mostly used for several reasons. The first is aesthetics and safety issues. The edge rounding process removes the sharp and dangerous edges of the workpiece so that no one gets hurt. Another reason is the requirements resulting from the painting processes. It is the sharp edges that are the most common source of corrosion, as the paint layer is very thin in these areas.

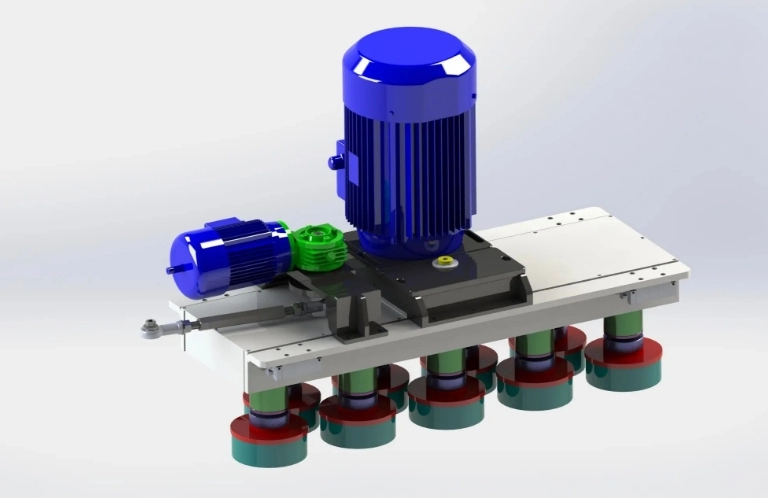

Edge rounding is essential in many industries, especially where safety and aesthetics of the finished product are key. This process involves the removal of sharp fragments resulting from cutting or mechanical processing. This is essential for safety and comfort. Madora machines are equipped with state-of-the-art systems that allow for precise and fast rounding, resulting in higher quality and longer-lasting products. We also deal with deslagging and removing strong burrs.

Edge rounding after plasma cutting, water cutting and punching

Laser cutting is extremely precise, but it can leave flashes or sharp elements. The rounding process involves grinding the edges of the components to give them a smooth, regular shape. Plasma cutting is fast, but can involve leaving an unsightly flash. In this case, deslagging and edge rounding are carried out. For this, angle grinders can be used to remove roughness, milling machines with rounded cutters for precise rounding and polishing wheels for a smooth finish. Punching also leaves sharp, uneven edges. Rounding them includes deburring (removing burrs manually or mechanically), grinding (using belt and angle grinders), edge milling and final polishing.

Why is edge rounding so important?

Edge rounding is a process that plays a key role in ensuring the safety and functionality of metal components. Sharp edges created by laser, plasma or water cutting can pose a serious risk to those working with these components. Cuts and other injuries are a common problem in industries dealing with metalworking on a daily basis. Therefore, rounding the edges not only minimises the risk of accidents, but also improves working comfort. This has a direct impact on productivity and production quality. Rounding the edges of components is particularly important in the automotive, aerospace and medical device industries.

Edge rounding is also becoming an indispensable step in metalworking for aesthetic reasons. Even the most precise laser or plasma cutting leaves edges that can appear rough and unrefined. Smoothing these edges with specialised equipment produces a visual effect that meets the highest aesthetic standards. The machines used for this purpose are equipped with a variety of abrasive tools that work with high precision to ensure an even finish. This makes the finished products look much better, which translates into user satisfaction and benefits the manufacturers’ reputation.

Corrosion protection is another important reason why edge rounding is so important. Sharp edges are particularly vulnerable to mechanical and chemical damage. This can lead to the rapid appearance of rust. The rounding process allows the paint to be evenly distributed over the entire surface of the component, including the edges. This makes corrosion protection more effective and significantly increases the durability of the products. As a result, edge rounding not only improves the appearance and safety of metal components, but also extends their life, which is of great importance in terms of production and operating costs.