Deslagging disc

The deslagging process is extremely important to ensure the quality and durability of metal components. Slags, which are a side effect of plasma cutting, can make subsequent processing steps more difficult. This is why their effective removal is so important, allowing for a smooth and clean surface, ready for subsequent technological processes. Deslagging is therefore, in addition to the removal of sharp edges, one of the processes for preparing metal elements for further processing, assembly or, for example, powder coating.

Professional deslagging is carried out using various methods, depending on the specific production process and quality requirements. Removal of slags from sheet metal pieces is an extremely important step. Why? For several reasons. The presence of slag, does not allow further processing of the workpiece. In addition, many manufacturers of metal components remove the slag for visual reasons.

Why does the slag form?

Slag is the result of complex physical and chemical processes occurring during the thermal treatment of metals. The plasma cutting process, which involves using a high-temperature plasma arc to melt material, occurs under extreme conditions. The high temperature causes the steel to melt and then cool rapidly. This in turn leads to the deposition of molten metal on the edges of the cut piece. Air blowing off molten steel contributes to the formation of inhomogeneous structures on the metal surface, which form slag.

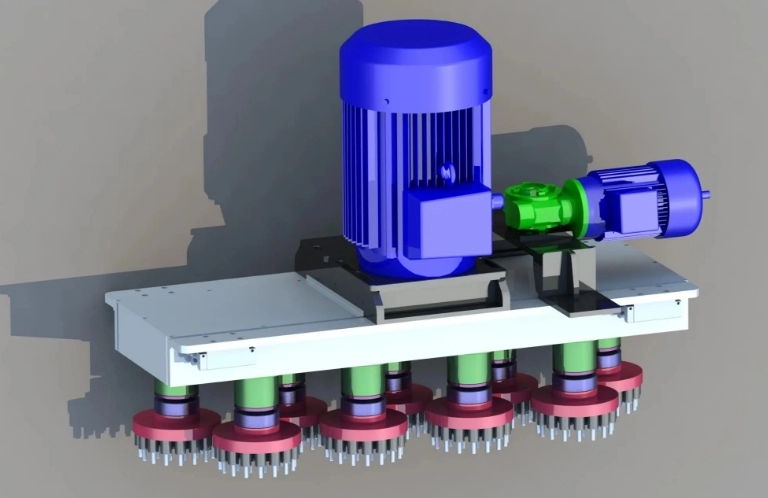

Automatic machines for efficient deslagging

Elimination of slag involves mechanical removal. This type of processing is most commonly used for cleaning components after plasma cutting. During this process, very severe slag is often formed, which is extremely labour-intensive and costly to remove. Streamlining this stage of work is possible through the use of automation. At Madora, we have developed an aggregate to automatically remove the slag. The device is equipped with a disc with steel fingers that move in a rotating and oscillating motion. By hitting the slag protruding above the workpiece, they effectively strip it away. Due to the long life of the consumables, this is a very efficient and cost-effective process.

Why should the deslagging process be carried out?

Removing slag from sheet metal is an extremely important process. Why? For several reasons. The presence of slag on the sheet metal surface can significantly reduce the quality of the final product, as well as hinder further processing steps. Leaving it in place may result in damage to the sheet metal even under slight force. In addition to this, many manufacturers of metal components remove the slag for aesthetic reasons. Its effective and thorough removal is therefore crucial to ensure the high quality and functionality of metal products.

Deslagging disc

A deslagging disk can significantly improve metalworking. This is particularly important for components undergoing plasma cutting. Thanks to the use of specialised machines equipped with discs with steel tabs, deslagging can be carried out automatically and with great precision. This disk, moving in an oscillating and rotating motion, strikes the surface of the metal, effectively tearing off unwanted fragments. The finger-like tabs are designed to maximise the effectiveness of slag removal, while minimising the risk of damage to the metal itself. The materials used to manufacture the discs are extremely durable and wear-resistant, ensuring long-lasting and trouble-free operation.

Benefits of using deslagging discs

There are many benefits to automating the deslagging process with steel discs. Above all, it significantly reduces the time needed to prepare metal elements for further processing. Traditional deslagging methods, such as manual grinding or sandblasting, are not only time-consuming but can also lead to uneven surface cleaning. By using disk-equipped machines, the process becomes more predictable and even. This translates into a higher quality final product. In addition, automation makes it possible to reduce production costs by decreasing working time and the consumption of consumables.

Another advantage of using deslagging discs is the beneficial effect on the aesthetics and functionality of the finished metal elements. It not only improves the appearance of the surface, eliminating unsightly tarnishes and bumps, but also prepares the metal for further technological processes, such as painting or electroplating. Slag-free components are durable and reliable, resistant to corrosion and other external factors. The finished products meet the highest quality standards of many industries. Automatic deslagging disks are therefore an integral part of modern production lines, contributing to the efficiency and competitiveness of companies.