Remove sharp edges

Removing sharp edges can have a significant impact on product quality and safety. In the metal industry, where precision and aesthetics are a priority, the elimination of unwanted elements is essential. Modern technology has made the process more efficient and less time-consuming. The machines to remove sharp edges manufactured by Madora ensure high performance. By automating this process, excellent results can be achieved in less time. This makes it possible to increase production efficiency and improve product quality. With many years of experience in the manufacture of machinery to process metal and wood, Madora offers customised solutions.

Punching metal parts with punches and a hydraulic press or cutting with a plasma cutter are processes that often involve problematic burrs. They are a serious obstacle during assembly. They also negatively affect the aesthetics and safety of use. For this reason, removing sharp edges is an essential step in the process of processing components. For many years, this activity was carried out manually with grinding tools. Nowadays, the process can be fully automated and – like sheet metal deburring – performed using special machines. Those manufactured by our company have been equipped with proven technical solutions that make them stand out for their very high efficiency and performance.

Removal of sharp edges

The removal of sharp edges is a key process in industrial production to improve the quality and safety of using the finished products. As an industry leader, Madora uses advanced technology and years of experience to effectively eliminate any imperfections on metal surfaces. Our deburring machines or machines to remove sharp edges are equipped with innovative systems that allow even the most difficult burrs to be removed accurately and quickly. It is indispensable in many industrial sectors, such as automotive, aerospace and household appliances manufacturing.

Sharp edges removal technology

The sharp edges removal technology developed by Madora’s experts includes a range of measures that are tailored to the individual customer’s needs. From the initial design of the machine, its manufacture, to service and technical support, every stage is handled with the utmost care. Our machines for removing sharp edges are equipped with advanced sensors and control systems that accurately identify and eliminate burrs. This makes the process not only effective, but also safe. Customers can count on the full support of our team, which is always ready to help optimise production processes.

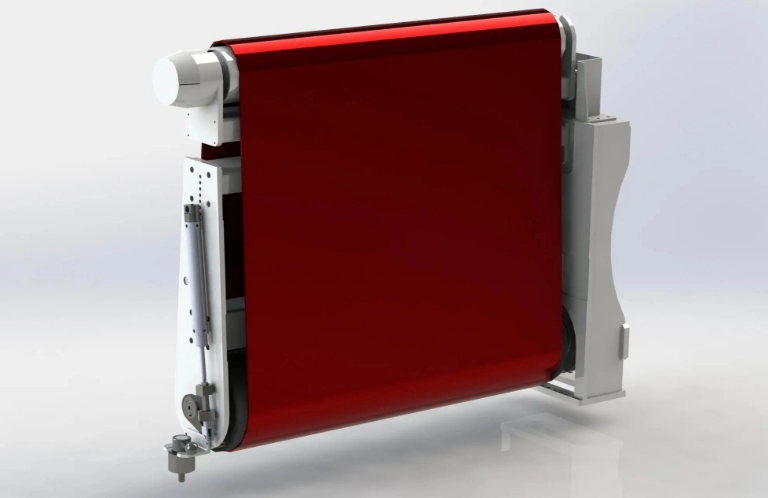

Endless belt grinding

Removing sharp edges is often useful when processing stainless steel. The small burrs are difficult to remove with tumblers and the abrasive discs wear out very quickly. Therefore, it is most beneficial to use a grinding process before the edge rounding process. With our machines, this can be done by grinding with an endless belt. The second process during which it is useful to use this technique is the removal of burr that is small and firmly embedded in the workpiece. In such cases, the tumbler discs alone are not always sufficient. Sometimes it is necessary to additionally use an aggregate with an endless belt.

Why invest in our technologies for removing sharp edges?

The sharp-edge removal technology offered by Madora brings many benefits to the metalworking industry. Above all, it allows a significant increase in the safety of use of finished products by eliminating sharp parts. In addition, improving the aesthetics of the products has a positive impact on their perception by customers. By automating the process of removing sharp edges, it is possible to increase production efficiency and reduce the costs associated with manual processing of parts. Thanks to the use of modern machines, it is possible to achieve excellent results with minimal effort on the operator’s part. This translates into greater competitiveness for businesses using our technologies.

The innovative solutions used by Madora allow the parameters of the machines to be precisely adjusted to the specifics of the material to be processed. This makes it possible to achieve optimum results regardless of the type of metal or the complexity of the workpiece. What’s more, we offer both machines used for processing metals and other materials, including wood planing machines to help smooth out surfaces. The technical support offered by Madora covers the full range of services related to the installation, servicing and optimisation of machines for removing sharp edges. The company’s team of experts is at your disposal to assist in every phase of the equipment’s use, guaranteeing long-lasting and trouble-free operation. Customers can count on professional advice and a rapid response to any problems.