Our company offers not only machines but also deburring tools in the form of discs. What is their function? They are some of the most important components of the entire device. This is because they are used to remove all kinds of residues left behind after performing cuts and other machining work on sheet metal. Moreover, they are also used for grinding sheet metal to make the edges softer and rounder. This is vital as sheet metal often has numerous sharp fragments on its surface after machining. Cleaning sheet metal of such swarf significantly improves the safety of all those responsible for further processing.

Deburring discs

We offer a wide range of deburring discs. Our product range includes tools for such applications as:

- descaling — removing even heavy scale from oxyfuel or plasma cutting, (deslagging)

- deburring and edge rounding — rounding off sheet metal edges and removing small burrs after laser cutting,

- heavy edge rounding — rounding off the edges of metal parts to an even greater extent,

- oxide removal — removing oxides from the lateral surfaces of metal parts after laser cutting,

- polishing — effective polishing of stainless-steel surfaces.

Madora's range includes deburring tools that are essential for any industrial metalworking facility. These tools are designed to maximise the efficiency of heavy deburring and descaling work, which is key to ensuring the high quality of finished products. Featuring state-of-the-art technology, Madora deburring equipment enables precise and fast deburring, minimising the risk of damage to the workpiece. The company offers an extensive range of tools that can be customised to meet the specific needs of each customer, making them ideal for a wide variety of industrial applications.

Durable and reliable deburring tools

The deburring tools available from Madora are characterised by exceptional durability and reliability, which translates into long-term use without the need for frequent replacement or maintenance. Each tool is made from high-quality materials that are resistant to wear and corrosion, which is particularly important in industrial environments. Additionally, Madora provides comprehensive technical support and service, a priceless added value for all users of Madora products.

The innovative nature of Madora's deburring tools is the result of many years of research and development in the field of metalworking. The company continues to invest in new technologies to keep their products at the forefront of innovation. Madora's deburring tools are equipped with advanced features that enable not only efficient but also precise deburring, which is essential for optimal results.

Deburring

Deburring is the process of removing sharp edges, burrs and other unwanted elements from the surface of the metal during machining. This is an extremely important stage in the production of metal components and is also relevant to other materials. This process aims to improve the quality and safety of the finished products. Deburring allows for smooth and even edges, which is particularly important in industries where precision and aesthetics play a key role. This process can be carried out using a variety of tools, both manual and automated. Our product range includes deburring discs, which are specially designed for efficient removal of sharp edges and smoothing of metal surfaces.

Advantages of deburring

Deburring can be important in terms of improving workplace safety. The removal of sharp edges and burrs reduces the risk of cuts and other injuries during further machining or assembly of metal components. In addition, smooth edges make it easier to carry out activities such as painting or coating. This in turn translates into a better surface finish. Moreover, it can also have a positive impact on the functionality and durability of the elements. As a result, deburring is not only a technological process, but also an important work step to ensure the safety and high quality of products in the metal industry. Deburring can also improve the aesthetics and convenience of finished products.

What materials can be deburred?

A wide variety of materials can be deburred, depending on the specifics and requirements of the production process. This method is most commonly used for machining metals such as stainless steel, aluminium, copper, brass and other alloys. Each of these materials has different physical and chemical properties, which influences the choice of appropriate deburring discs and techniques. Stainless steel, due to its hardness and corrosion resistance, requires high-strength tools. Aluminium, being a soft and lightweight material, is easier to work with but requires precision to avoid surface damage. Components made of synthetic materials can also be deburred.

Deburring methods

Deburring is a process that can be carried out in many different ways, depending on the specific material to be machined and the surface quality requirements. One of the most commonly used methods is mechanical deburring. It involves deburring using hand tools and. The effectiveness of this method depends largely on the operator’s skill, which can affect the product quality. Therefore, in many cases, especially when high precision and repeatability are required, specialised deburring discs are used. They are designed to ensure even and accurate deburring, resulting in better quality and safety of finished parts.

Another advanced deburring technique is the method using high temperatures. The process involves placing the workpiece in a special chamber into which a mixture of oxygen and methane is introduced. The controlled explosion that occurs inside the chamber results in the removal of sharp edges from the metal surface. Another deburring method is the chemical technique, which involves immersing the workpiece in special etching solutions. There is also electrical deburring. This process involves attaching an electrode to a current source, making the workpiece an anode. As the current flows, the surface is smoothed by electrochemical removal of sharp edges.

Deburring discs

Deburring discs are available in a wide range of variants, making it possible to match the right ones to the specific needs of different metalworking processes. The most popular are discs available in various sizes and shapes for precise deburring of different surfaces. They can be made of a variety of materials to ensure high durability and effectiveness. Another type of tool is hand and power files, which allow fine finishing of edges and hard-to-reach areas. For more advanced deburring processes, machines with specialised heads are also used to automate the process and make it more efficient.

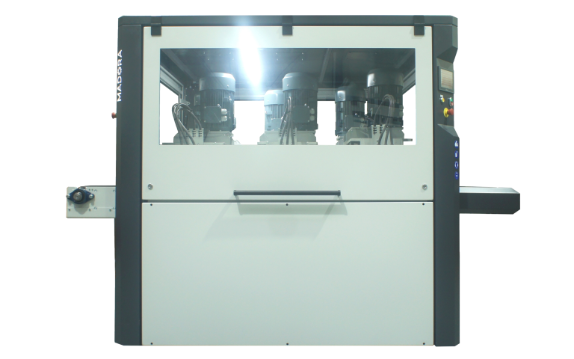

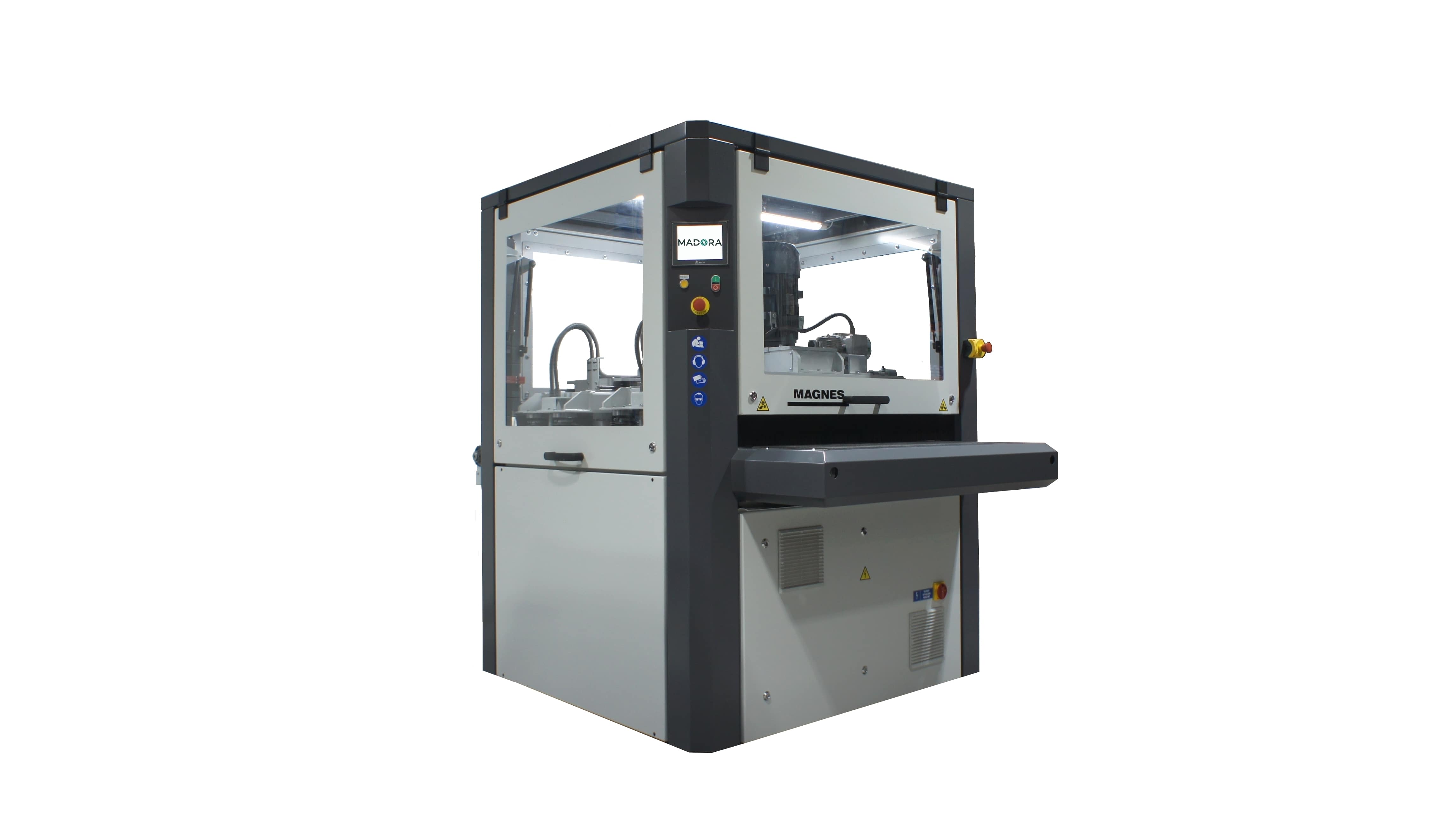

Deburring machines

A deburring machine is a specialised device designed to remove burrs, sharp edges and other unwanted features from metal surfaces. Such advanced machines are key tools in the metalworking process, ensuring high quality and safety of the finished products. The principle of their work is mechanical abrasion; they are used to precisely remove excess material and smooth the surface. Thanks to the use of modern technology, our deburring machines ensure high productivity and precision. They feature innovative control systems that allow the operating parameters to be precisely adapted to the specific requirements of the task at hand. This makes it possible to achieve optimum results with minimal use of tools and materials.

Types of deburring discs

Deburring machines can be used to process a variety of materials, making them versatile equipment in the metalworking industry. In addition, our state-of-the-art equipment is designed with ergonomics and safety in mind. The solutions used in them allow for efficient and safe use. An advantage of our deburring machines is their ability to operate continuously, which is particularly important in mass production. Thanks to their high reliability and durability, they can operate for a long time without frequent downtime for maintenance or tool changes. This in turn translates into increased productivity and reduced operating costs. Deburring machines are indispensable for any modern industrial metalworking facility.

What distinguishes Madora deburring machines?

Madora deburring machines stand out in the market thanks to their reliability and ease of use. Each machine is designed to minimise the risk of damage to the workpieces, resulting in a high quality final product. In addition, our company is constantly investing in the development of new technologies to meet the growing demands of the market. Each deburring machine features advanced functions to enable precise customisation of the working parameters. The equipment is extremely versatile and can be used in a variety of industries. They are the ideal choice for companies looking for flexible technology solutions.

With many years of experience in the manufacture of metalworking machinery, we have gained the trust of customers from many countries. We focus on the quality and innovation of our products, which makes our company a leader in the deburring machine industry. Each of our customers can count on an individual approach and full technical support. Check out our range of products. Please, contact us in case of any questions.