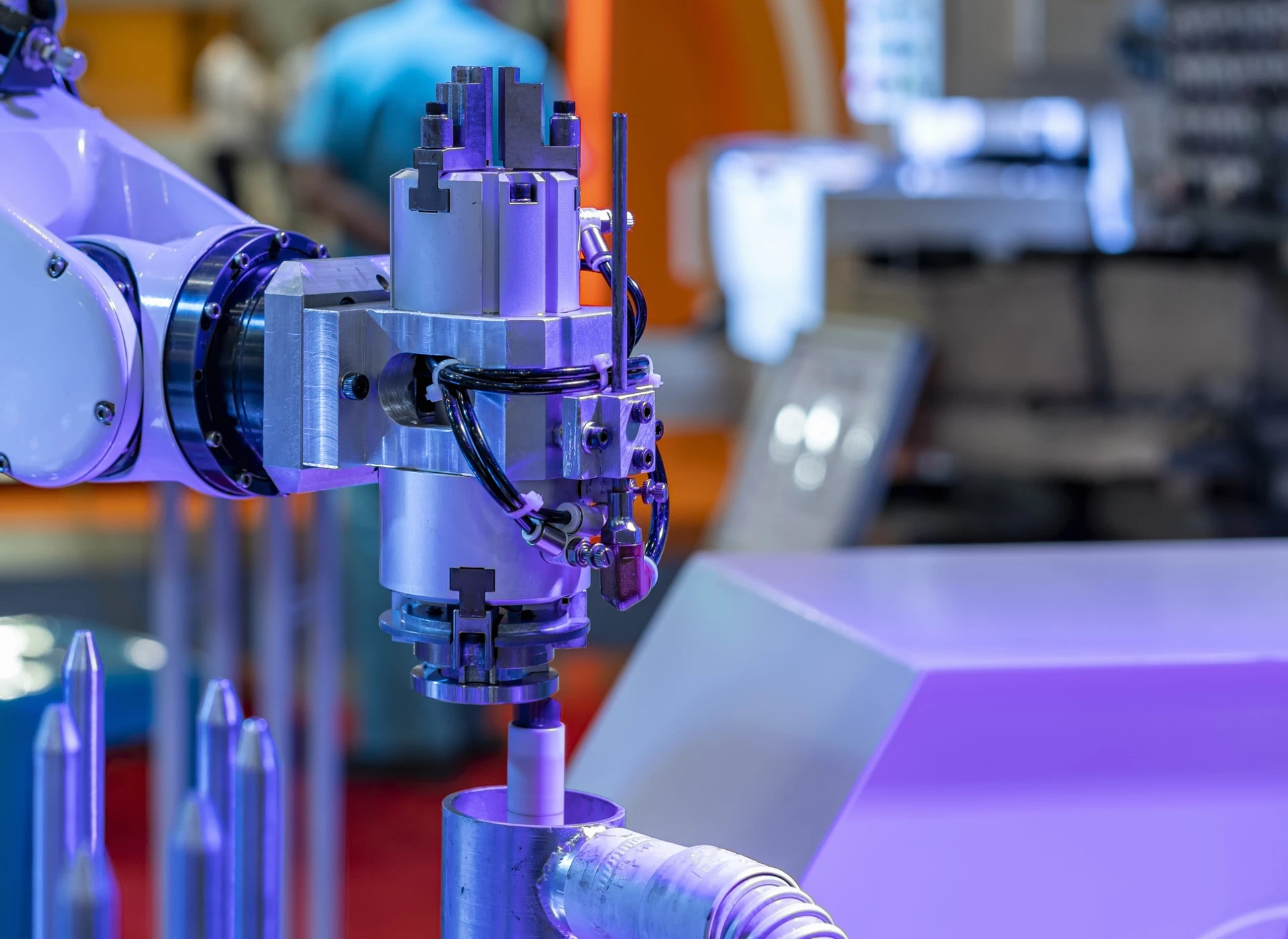

Modern sheet metal deburring machines must meet a range of requirements to ensure processing efficiency and quality. Performance, precision, and versatility of applications are key features that should characterize these devices. Understanding these aspects is essential for anyone planning to invest in modern processing technologies. Attention should also be paid to the technical support and service offered by manufacturers, as these can significantly impact long-term user satisfaction with the machines.

Blog

We encourage you to read our blog articles.

Sheet metal grinding is a crucial process in metalworking that requires the right machines. The proper equipment influences work quality and efficiency, which is important for the safety and durability of products. Therefore, choosing the right machine for sheet metal grinding is key to achieving the desired outcomes and avoiding issues.

Modern metalworking machines are revolutionizing the industry by introducing innovative technologies that significantly enhance the quality of metal surfaces. In this article, we discuss how these devices impact production processes, increasing efficiency and precision in manufacturing.

A thicknesser plays a crucial role in the production process, significantly impacting both efficiency and product quality. This article explores the advantages of using this tool across various industries and examines its impact on the operational efficiency of industrial facilities. This insight will allow for a better understanding of the importance of a thicknesser in metalworking and an appreciation of its advantages in terms of market competitiveness.

Woodworking is a process that requires the right tools and skills to produce high-quality results. The planer machine is one of the most important tools in this field, but there are also manual techniques that can be used for this purpose. In this article, we will discuss the differences between these methods, their application and their advantages and disadvantages. We will also consider the impact of modern technology on the machining process and the criteria for choosing the right planer machine.

The double-sided planer plays a key role in the production of wood flooring, influencing the quality and efficiency of processing. By processing two wood surfaces simultaneously, the machine speeds up the production process, which is important in the industry. In this article, we will outline the changes in flooring production thanks to double-sided planers and the benefits they bring to manufacturers, giving a better understanding of their importance in this sector.